|

I'm keeping my head down this summer on the Would-Be Farm, trying to get that novel of mine out and about. Mr. Linton, on the other hand, has been getting stuff done around here. We just acquired one of the cooler bits of kit in the barn: a flame-thrower. No joke. It's a chemical-free means to a weed-free end. Need I mention the anti-zombie potential? My favorite skipper built a woodshed (a structure that is both made of wood and designed to contain wood, okay, Lisa?) next to the sauna. We'd had a covered woodpile, but the amount of firewood that got burned since the implementation of the wood-powered sauna led to a step up in the firewood game at the Farm. Constructing a shed sounds a blithe enough pastime, but with neither plan nor drawing? Himself claims to be a rough carpenter, but he is adding skills with each project. I say so despite the sage advice of Sippie and Bonnie both... Between construction/destruction activities, plus the occasional sailboat race (go Team New Wave!), there's always lawn work. Meadow and woodlands surround us, but Mr. Linton keeps the trails and the lawn properly neat by the use of no less than two trimmers, two mowers, and a tractor. Not simultaneously. Yet. Whenever the weather cooperates (growing grass, self-imposed deadlines, and encroaching thorn apples be danged!), we fish.

4 Comments

There's a theory about value called the "IKEA Effect," whereby people over-estimate the value of something they have themselves made. We got to test it out this spring at the Would-Be Farm. From Estonia by way of New Jersey, thank you BZB Cabins for a pallet's worth of parts, 24 pages of instructions, and a very helpful expert only a phone-call away. I grant you, we poured quite a bit of effort into this longer-than-any-danged-weekend project. If the value increases as a result of how long it took, and how many new neural pathways it encouraged, and what fresh language it encouraged (is that hangy-downy part of the roofing shingles called a "fang" or a "bump"?), well, all to the good. And the refresher on metric measurement? Nigh on priceless. But regardless the IKEA effect. Fer reals –– this thing is hella neat-o. And so toasty!

Why have I made more than one petticoat this autumn? Is it texture? Volume? Swishy-swirly goodness? A latent Miss Kitty* crush? An elaborate plan to avoid writing? *Oh Lawsie, do NOT –– as you value and respect the variety of human experience and preference –– DO NOT google "Miss Kitty" + "crush" or "fetish" or "kink." True story: I was once a 21-year-old editorial assistant in Manhattan. I worked 70 hours a week for a pittance (the word derives from people given money from pity -- which is not actually a stretch for independent book publishers at the time). I was in the office with William Dang Golding, Susan Freakin Sontag, Roald BFG Dahl, Holy Moly Madeleine L'Engle, Czeslaw Eyechart Milsovic, Polly Amazing Horvath, Maurice Himself Sendak, and Rapmaster Seamus Heaney, to drop but a few of the lifetime's worth of literary rockstars I met. I loved that time of my life. My coworkers included people who were famous in literary circles in their own right, as well as actual Guggenheims, a genuine English Lady Somebody–– the kind of folks who habitually went not just to the Hamptons for the weekend, but to Morocco. A country church-mouse, I was just that tiny bit too poor to afford the subway for trips less than 40 blocks (my rule so I'd hoof it between Penn Station and Union Square daily). Fancy-schmancy college had exposed me to the other, very wealthy side of the tracks, but still––! Bonus side-benefit of scholarshipping my way through school: the crippling flush of envy had pretty well burned all the way through me. And as for blending in to the trés chic Manhattan publishing scene? Errrm, even a minty-fresh Sears chargecard wasn't gonna godmother me to that ball. I embraced vintage. There was a gorgeous Pendleton plaid suit, an old Chanel number from a garage sale, a handful of thrifted cashmere sweaters. I wore my riding boots with skirts, sported stacks of fake pearls from my grandmother, and sometimes I put together outfits that swooped past the line of "costume or not?" with joyous abandon. Today, fashion historian Morgan Donner might call my choices "history bounding." Or as the cool kiddies put it: #Historybounding Still and all, fallible me at 21 or 22 saw a tourist descending the escalator to the tracks in Grand Central Station on sultry August day and was struck DOWN with want. She was wearing exactly the item of clothing I coveted. Of all of the many MANY desirable commodities available in the big city, I wanted what she had. A full, pale, ankle-length skirt with an antique, Edwardian vibe. That skirt! Lacking that kooky booty seen with late Victorian bustles, this item of mere clothing managed to be curvy but straight, with a sensible, workable air. I thought it made the wearer look interesting and self-confident. It was perfection. I looked high and low for that skirt. For actual decades. Chasing an ideal. And even after I had been sewing stuff for ages ——I'm on my third sewing machine, for the love of Captain Pete Obvious! —— it only came me to this year: "Yo! Self! Why not make that skirt yer own dang self?" And so, dear Reader, I am. After a rush of creative energy, snipping of threads and hacking my way through historical methods of pattern-drafting, I have what I have longed for: a long skirt with pockets deep enough to double for a handbag.

A few of my YouTube mentors: Bernadette Banner, Morgan Donner, Rebecca at Pocket Full of Poseys, Ora Lin, and Marika at Enchanted Rose Costumes. I made one walking skirt from denim. I'm making another from a single thrifted yard of pretty plaid wool and the remains of –– as God is my witness –– velvet curtain panels from Ikea. And under the skirts, a wealth of swirly, swishy petticoats in flannel and cotton lawn.

If the internet has taught us nothing, it's that there are more random activities to generate human joy than anybody can shake a keyboard at.

It's just a hop, skip, and a jump from hand sewing a pirate shirt to creating cordage from plants, right? A mere matter of, oh, 400 or so centuries into the past. In prehistory, plain cordage (aka twine, yarn, two-ply thread) was used for snares, nets, for lashing x to y, and, step by step, into fabric. Many plants –– nettles, willow, basswood, berry brambles, burdock, rhubarb, etc., etc. –– grow stringy fibers known as "bast." It's a thing I missed learning as a kid, though I was fascinated by wildcrafting in general. The Would-Be Farm has enough bast-on-the-hoof to keep a schoolbus full of crafty cordsfolk busy until the next Ice Age. And so during this summer's regatta roadtrips, I have been spinning straw into gold. Rapunzel and that patient sister with the enchanted swan siblings? They got nothin' on me. Wither went I, along came the bundle of dried plant, a glass of water, and piles of chaff. My technique improved with each ell.

Regardless the state of the world, and the awful things that are going bump in the daytime, the Would-Be Farm is full of urgent and pleasant chores. It's the first thing on my spring chore list: Clear trail. Which means cutting up fallen logs (both emerald ash borer and something that might be pine beetles are burning through the woods). Much farther down the list, but equally important for navigating is to locate the two critical culverts in the big field. Because nobody likes to slip into the ditch. The grass is more than 4 feet tall in places, so there's an element of fun and danger in scouting the way in the 4WD mule. There's other tidying to do, like sweeping up pollen and other detritus at the –– still critter-proof! –– gazebo in the woods. And installations! Last December, my favorite skipper constructed two bat houses and a barred owl nesting box for me. It wasn't chinchy to get this first one mounted on a 20-foot pole and then –– like the mother of all mast-stepping moments –– raising the pole upright and settled into its post-hole, but the result is magnificent. We hope the bats find it and make it home. The local populations are –– we hear –– rebounding from white-nose-fungal colony collapse. Sadly, since we are only part-time farmers, and because poultry are not notable for excellent traveling habits, we don't plan on adding chickens to the mix. Good thing we have good neighbors who could not walk past that stock tank full of tiny chicks this spring at the feed store. And you do have to buy six at a time. In addition to being unable to resist the charms of chooks, the neighbors have a 6-year-old granddaughter who has nothing more pressing on her to-do list than to hand-tame the chickens. I'm thinking about sewing them (and her) matching tutus. This summer's largest project hones Jeff's carpentry and patience both. Without the camper trailer to protect, the shed suffered a bit of a breakdown, or possibly a depressive episode of some kind, drooping visibly and listing downhill. The strategy that seems to work for us (QED, baby!) when this kind of thing occurs in our lives, is to get help, get to work, and find new meaning. Transforming the shed into a barn has meant shoring up the structure and adding a concrete floor. Followed by enclosing the space and helping it to a new identity by color. And when not holding metal panels in place while Mr. Linton does his drill thing, I have about a thousand daffodil bulbs to re-arrange. I started in 2015 by transplanting "Scrambled Eggs" a fluffy double-flowered daffodil, from where the previous owner of the farm had bedded them by the old farmhouse. I wanted them where I could see them, so I stuck them hither and yon. They are prolific and have doubled, tripled, quadrupled in number. As some may remember, my sweet mother-in-law and I put in 200 or so jonquil bulbs a few years ago. They too have multiplied and started to crowd one another. Plus she gave me dozens of bulbs to start in Florida this winter. It's not a kind climate for jonquils, so those bulbs also came to the farm. I transplanted or replanted maybe 200 bulbs last week. Digging up the plants, feeling for the bulbs amidst the other roots and rocks, removing them feet first through a chunk of turf, then putting each chubby knob back into its own neat divot...I don't know what else will come next spring, but I thoroughly expect to have a glorious crop of flowers.

After some thought, we decided against doing our own concrete work. The guys managed to dig, gravel, and move the concrete by wheelbarrow from where the 'rete truck backed into Jeff's velvet field of green in a single day. (PS, it took us only a week or so to fill those ruts and overseed the area with clover. The scars on the field are nearly invisible.

So steps.

I meant to just put a couple of flagstones into the ground, but then the stones started piping up and the hill was asking for more...

Somehow the very idea of work get the stink eye –– golly, we wouldn't even wish it on our animal friends. The same animal buddies whose stalwart character and skills we've selected for across hundreds of generations.

But did any of us evolve all these years find our joy while melting into the upholstery? Add a bag of chips and a winning Lotto ticket, et voilá! The American Dream nirvana! I don't mean to rant. Or actually I do. I just don't want to glaze anyone's eyes for them. Save the anesthetized stare for the third season of whatever's streaming today. Grrr. What kind of malarkey are we putting on toast? I'm not above it, truly. Work can suck. Carriage horses sometimes die of heat exhaustion. Racehorses twist an elegant ankle and are seen no more on green pastures.

But can a person deny a horse the joy of running? The snarfling satisfaction of a well-fetched stick? The sweaty pleasure of that last log split and stacked?

As anyone who knows my fondness for Archie MacPhee will testify, I am liable to announce a propos of nada: “Sharks have no bones!” It was a catchy tagline from a catalog some years ago. And true. Shark are all cartilage and attitude. And, as one might discover on a foggy January wander along a beach – teeth. Sharks continually shed teeth and grow more. Row after row of them.

Walk down the right beach and tune your attention to the y-shape, and dozens of teeth will appear.

Which makes sense, because sharks have been swimming about for millions of years. And some grow up to 35,000 teeth in a lifetime. I suppose someone has done the math, but it’s a lot of teeth underfoot. One might say, the opposite of hen's teeth, even.

Doesn't everyone have this impulse to shuffle chunks of granite or marble or gneiss from one place to another?

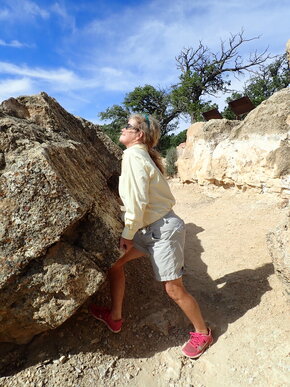

Perhaps the rock-moving thing is in the blood. Heaven knows there are stone workers by the shovel-full up the family tree: tin miners in Cornwall, copper miners in Tennessee, the odd silver-miner crushed in freak accident in a Colorado mine.

His reserved "hello" morphs into a grinning, winking welcome. "Oh! If only..." he always ends up sighing. Charming Aunt P makes conquests left and right. I know she had the quarryman and his crew move and readjust rocks over and over and over again until she had her flagstone patio just the way she liked. It's to her credit that the quarryman made it beautiful and remembers her fondly.

You have to listen to them or learn to live with some half-assed, unbalanced construct. What can be more beautiful than an elegant old stone wall? Running mostly straight, like a seam across a landscape -- ooh, ahh.

Before google was a verb, we passed one North Country blizzard by pulling "Stopping by Woods on a Snowy Evening" –– stanza by sing-song stanza –– from imperfect collective memory. I remember the blue light of the overcast sky reflecting ice into the dim living-room. The sinking presence of cold at the glass. And the dozens of running, stumbling starts it took for one of us to finally say the poem complete from start to finish.

* My favorite Sumerian quotation is "there is nothing new under the sun." Which, as it turns out when I research the citation, isn't Sumerian at all but Ecclesiastes. Huh.

My second favorite Sumerian quote? "What kind of a scribe is a scribe who does not know Sumerian?" This is the longest stretch in his adult life that my favorite skipper has spent away from sailboats. For decades, we schedule our year around various regattas. We've missed weddings and birthdays because of our sailing calendar. As I remember, we'd been together for five years before taking a trip that was NOT related to sailing. Because of regattas, we've traveled to Italy and Sardinia and Greece and all over South America. And North America. Hawaii even. The year the Flying Scot North American championship was held in Texas, we planned a summer adventure that took us looping out West. All for competition at the mercy of wind. Racing on the bounding main –– it's a sport, a calling, a joy. It's the bones of our life together. Then along comes the Covid-19 Pandemic, leaving us high and dry. Which is how we've managed to finish the Woodbee in a matter of months. When last we left the build, the 600-square-foot structure was dried in, with a pair of walls and a loft accessible by pull-down ladder. Jeff and I had put down flooring, slathered paint on everything that held still, and set the wood stove into place. When we arrived in late April, the list of to-dos was not inconsiderable: walls, plumbing, electricity, kitchen, bathroom... And a drumroll, please.... |

About the Blog

A lot of ground gets covered on this blog -- from sailboat racing to book suggestions to plain old piffle. FollowTrying to keep track? Follow me on Facebook or Twitter or if you use an aggregator, click the RSS option below.

Old school? Sign up for the newsletter and I'll shoot you a short e-mail when there's something new.

Archives

June 2024

Categories

All

|

RSS Feed

RSS Feed