|

Why yes, I was briefly addicted to Days of Our Lives in the era of broadcast television. My grandmother and my sister used to gossip on the phone about the Hortons and Bradys of fictional soundstage Salem, and frankly, I wanted in. Plus the daytime drama fit perfectly in the timeslot between the noon and 2 pm shuttle runs when I was a cheerful first mate on Captain Alva's shellkeyshuttle.com in Pass-a-Grille. I barely remember the storylines, engrossing as they seemed to be. One scene lingers, an uncomfortable bit with a stalker and a victim and the screen fading to black over an eerie recitation of Yeats' "When you are old and grey and full of sleep,/And nodding by the fire, take down this book,/ And slowly read..." When I consulted my sister, she remembers several literary moments during that era of the program. I imagine one of the show's writers gleefully setting gems she'd mined from her education into this lowbrow, La-Z-boy throne of American culture. Still, it's the tagline that really sings. I reference it frequently when looking at a calendar. We've already swooped past Midwinter Regatta season. A photo recap for your reading pleasure: Other sailing events have dropped over the horizon: we helped run an ACat regatta, Jeff sailed the Round the Point race, as well as squeezing in an IC37 regatta in Lauderdale and a full-moon race. The sands of time sure do hurry through that hourglass. Which means, as tumbling grain follows tumbling grain, it's nearly time to check on the Would-Be Farm.

To each season its own joy.

0 Comments

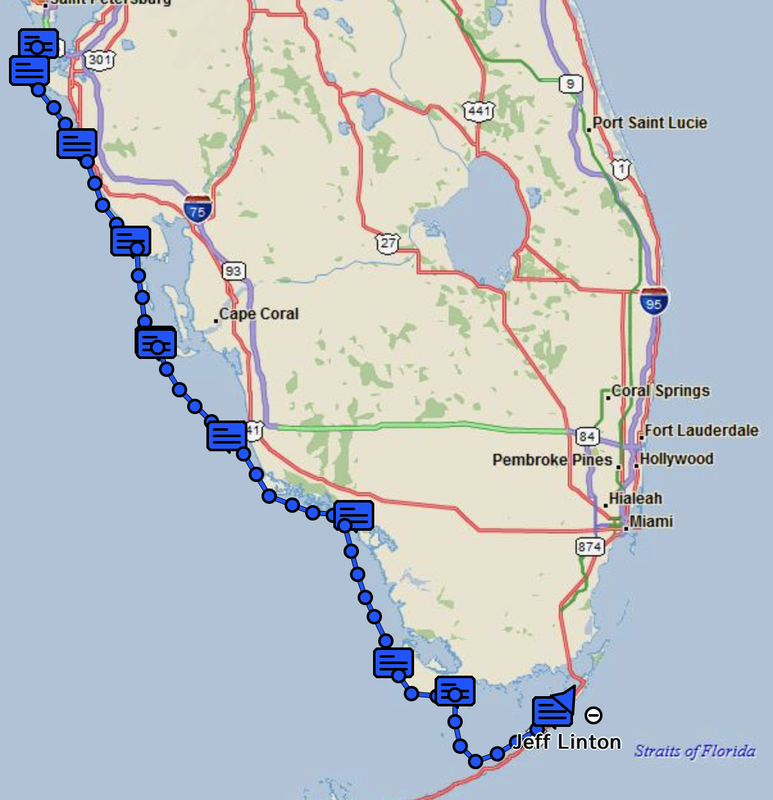

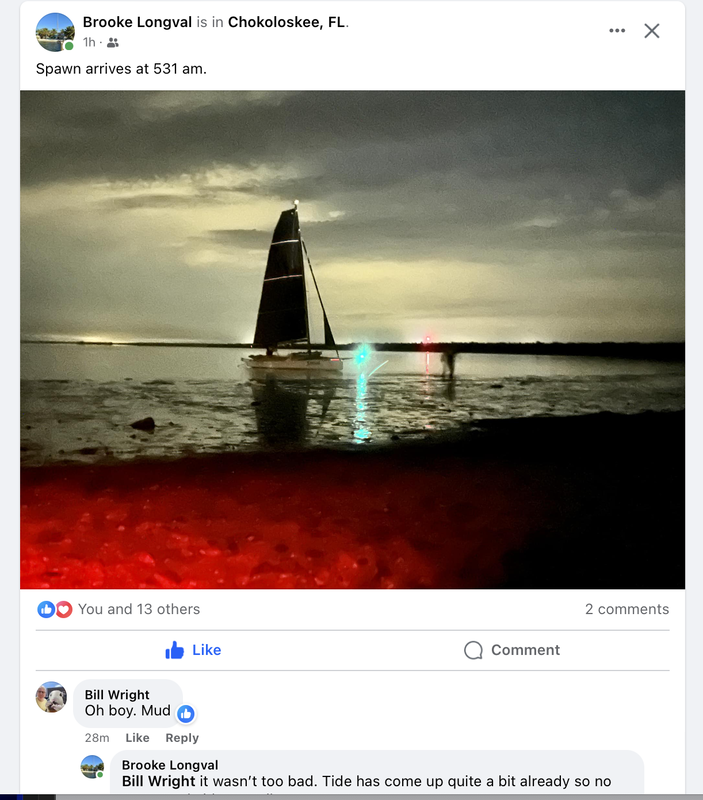

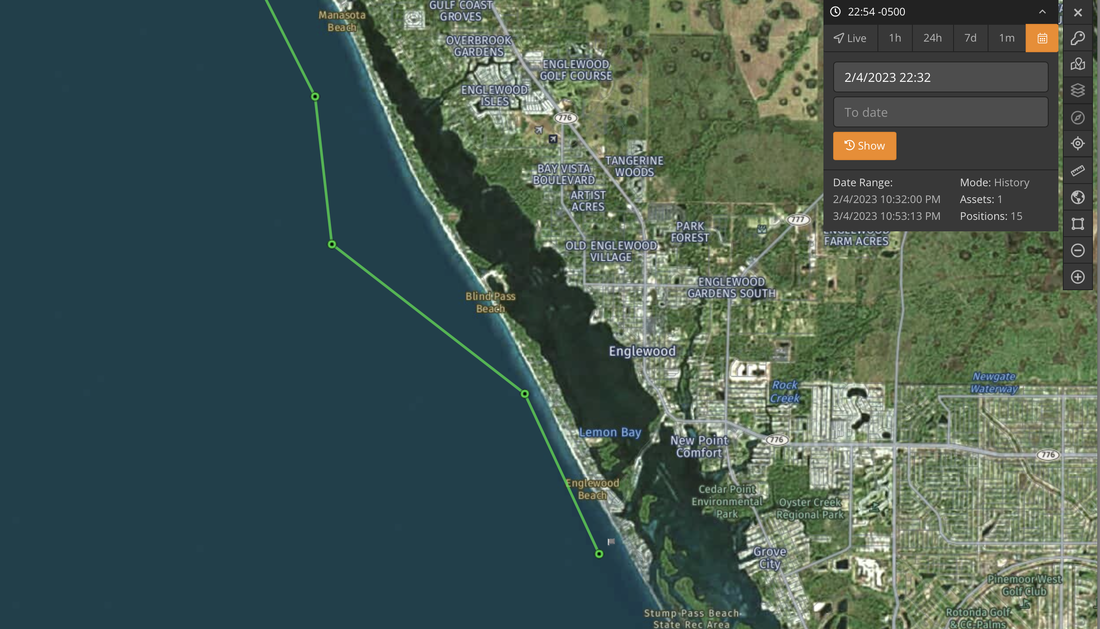

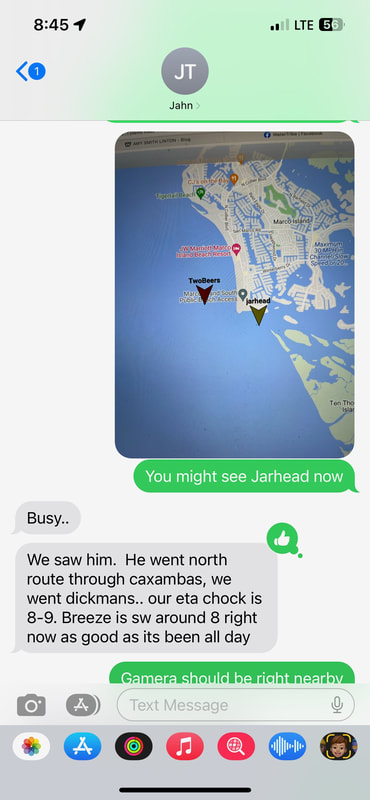

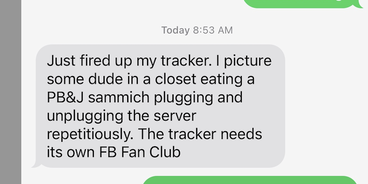

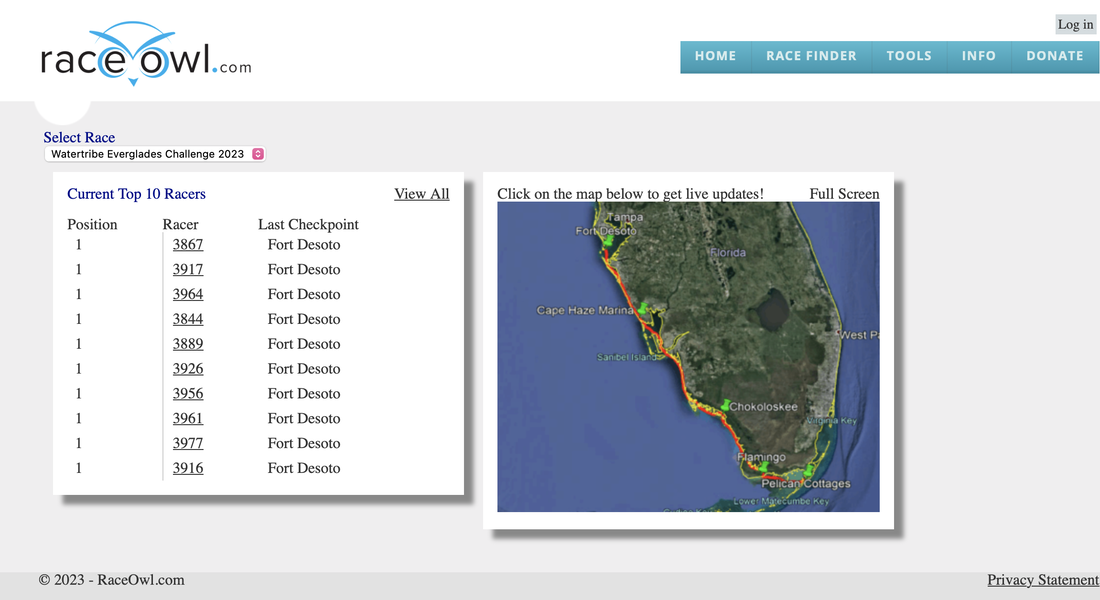

73 hours after pushing off the beach in Fort DeSoto, TwoBeers and Moresailesed arrived safe in Key Largo, completing their 2024 Everglades Challenge. It's been 10 years since that first expedition, when it was the original Frankenscot. These days, with Spawn having been designed FOR this event, I'm less worried about the team arriving alive. But stuff happens, which is why they have 2 hand-held radios, 1 Velocitek electronic compass, 2 smart phones, 1 tablet for navigation, 2 safety harnesses, a packet of paper charts, a personal emergency beacon for each sailor, and 1 personal tracker on the boat. 16 times this year before finishing, they pressed that OK button on their tracker. The Garmin InReach proved itself definitively 4 metric buttloads better than the SPOT personal tracker. SPOT, having but the 1 job, did not track my person. Garmin InReach did, every 10 minutes—without drama, attacks of the vapors, or random skips. Thank you Garmin. I don't think I am going to stop mentioning that for some years. 27 is the number of times the water pump was deployed. This is higher than normal for the trip, and weren't the fellas glad to hear the cheerful little battery-powered pump kick on! Each of the wide wings of Spawn contain a water-tight compartment that ballast the boat. The little pump pushes water into a tank as directed; the tank empties by way of a round port and a vent. It's like having an extra crew hiking on the high side—a big fat crew who doesn't eat, complain, or cut into the supply of beer. It's been handy when the boat is on a long tack, but this year, they found themselves flipping the switch a lot. Even with a quarter-tank of leverage, they maximized power whenever the wind permitted. 13 times in the course of the 300-mile adventure, the wind slicked out. Meaning the Gulf of Mexico or Florida Bay or whatever body of water was like glass, showing absolutely no air movement. Which is not so great for a sailing vessel. Like in the Rime of the Ancient Mariner: "Day after day, day after day/We stuck, nor breath nor motion;/Idle as a painted ship/Upon a painted sea." 2 is the number of oars aboard. Luckily, Spawn was built for glassy conditions as well as sporty ones. My favorite skipper has outfitted the barkey with long sweeps and a sliding rowing seat. They were able to buck the tide at Stump Pass with help of those long oars. It also kept them moving when there was no other power available. Other WaterTribesfolk during this year's challenge converted their sailing vessels into b&b's or Ronco pocket fishing platforms. Unluckily, the team was out of training for rowing. 9 out of 73 is the estimate for the number of hours the Spawnsters rowed or row/sailed during the event. The number of miles is unknown: high math and calculations of tidal flow are beyond us at the mo. 20 is the number of minutes for the rowing watches. That is, first one guy rowed for 20 minutes, then the other guy rowed for 20 minutes. They did this for a perhaps 10 miles off Sanibel, plus many passes, plus just "for a while" off the Everglades. Rowing machines takes on a new meaning. Meanwhile, the kayaking division of the WaterTribe was rubbing hands in anticipation of beating records without having to battle winds and waves. Alas, the tide... 1 is the number of times Spawn took breaking water over the bow this year. While heading toward Everglades City, a Karen on a crab boat decided it was time to teach a sailboat a lesson about using the channel. With headlights on hi-beam, the 35-or-so footer charged at them in the narrow channel, veered across their bow at a prodigious clip, then cut back so that their wake shot green water across Spawn. This while Spawn was hugging the right side of the channel! Like an 18-wheeler swerving into oncoming traffic and then passing on the shoulder. Were our intrepid sailors sporting their drysuits? Were discouraging words bantered about? Did cooler heads later agree that this was yet another reason not to carry rocket-launchers? The crab boat was not sorry, btw. 1 is the number of waterspouts spotted by the team early Monday night. Just as TwoBeers reached for his phone to take a photo (I know, I know, calm down! We are all allowed to evolve and grow, people!), the tornado-shaped whirlysnake slithered back into the cloud bank over Cape Sable, leaving the rowers without even a puff of air to help them along their way... 1,000,000,000 is the number of stars shining over Florida Bay late on Monday night of this year's challenge. A few days of clouds and haze cleared, giving way to an astonishment of spark far from the loom of artificial light. The on-the-water portion of Team Spawn rarely wax poetic, but they reported that the night sky was indeed magnificent. 3 meals of fried chicken were consumed, along with 3 breakfast shakes (2 strawberry-banana and one––so healthy!––Fruit Loop flavored) 3 oranges (but not avocados) and 2 bags of homemade beef jerky 4 or so boxes of Kind and granola bars 2.5 baggies of chocolate bark (pairs well with rowing), and 1 energy-pill jar of mixed jelly beans and Hot Tamales 1 single can of Mountain Dew (on dawn on Tuesday, when the wall was about to be hit) 4 mugs of instant ramen noodles (checkpoints 1 and 3 were the Noodle Kings and Queens) 2.5 jars of trail mix 7 1-liter-bottles of water, frozen and then melted 8 bottles of Gatorade and 1 bottle of sundown beer per day. Leaving, naturally, 2 beers on arrival. 2 is the number of large sharks Moresailesed and TwoBeers spotted in Florida Bay. Large being over 4 feet long. 1 a jumper whose splash may have startled our aquanauts out of a solid, head-nodding, drive-over-the-rumble-strips snooze at the wheel. 35 is the number of people who texted or called in the last 30 hours of the race. Thank you for checking in! 754 is the number of times Bookworm clicked refresh and reload on the most excellent RaceOwl race tracker. And not just for me to watch my guys. There's MadMothist, Sailor King, AndyMan and NateDog, Jarhead, Yarddog, and so many more whose progress I checked. It's the sort of tick that will cling for a few days, when I bolt up from deepest sleep and continue to monitor the progress of the racers. 1 is the place our Spawnsters ended up. Officially, I believe Chief awarded them the title of "Slowest Ever First Boat to Finish." Still, on the dusty white beach at the Pelican Resort in Key Largo, the gang of welcomers included Matt and Jody Koblenzer of Key Largo from the 2.4 Meter Class, Keys Realtor and Flying Scotsman Jim Signor, and a few of the Tribe: the Chief, PaddleDancer, Mrs. Bump and Turn, Skip, Mrs. MadMothist, Possum, plus a nice vacationing couple from Alaska who know the R2AK and are checking out our southern-fried adventuring. I can't actually count the blessings. Thank you for following and cheering the fellas on and for giving me the excuse to tell this particular story. Until next time, sportsfans...

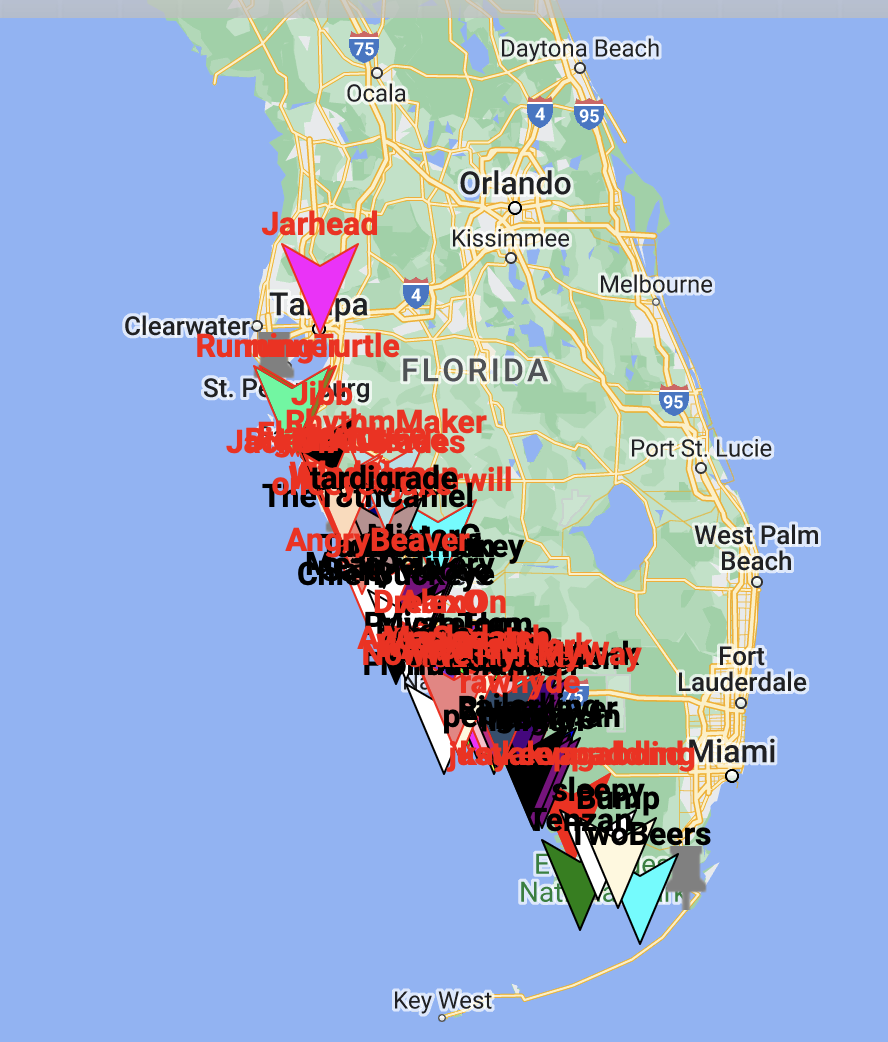

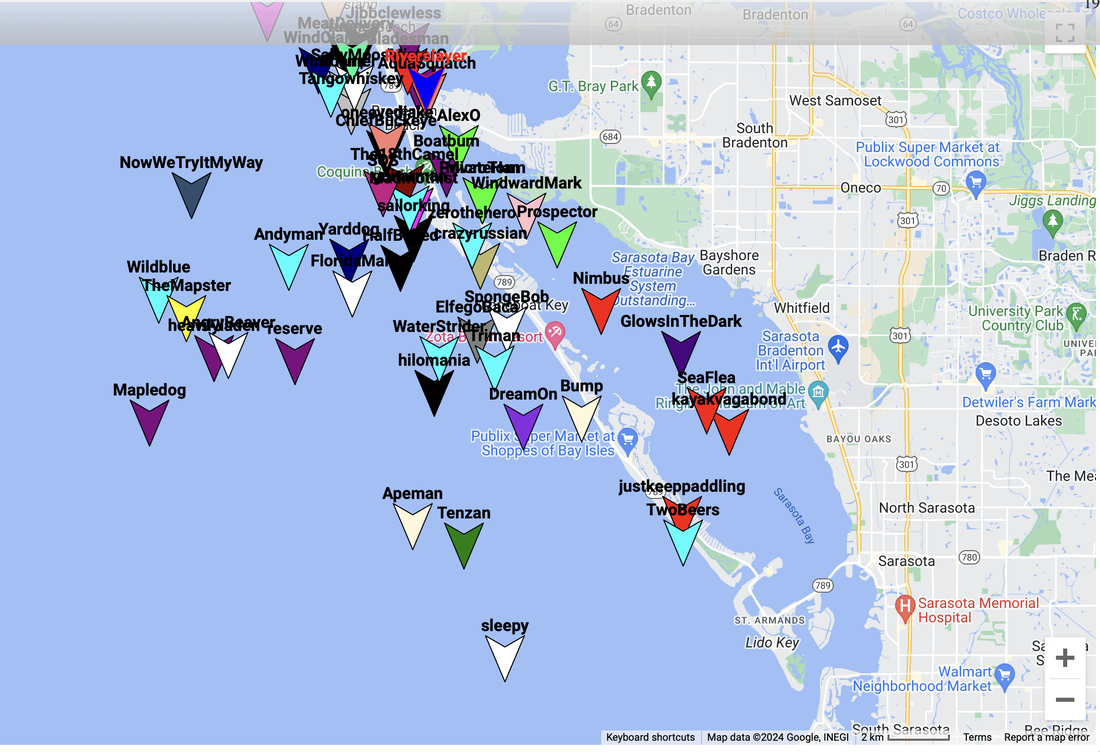

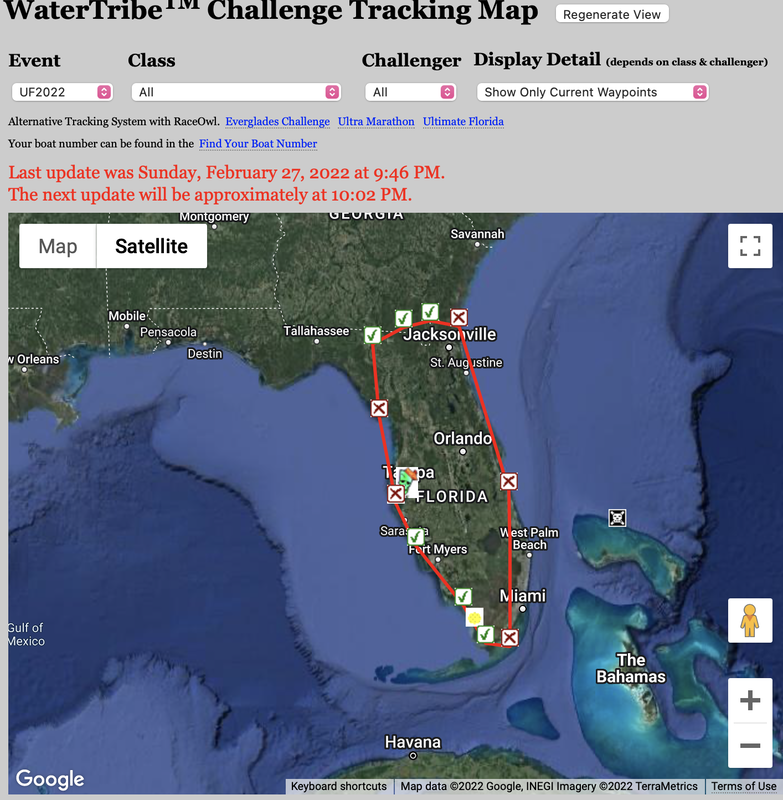

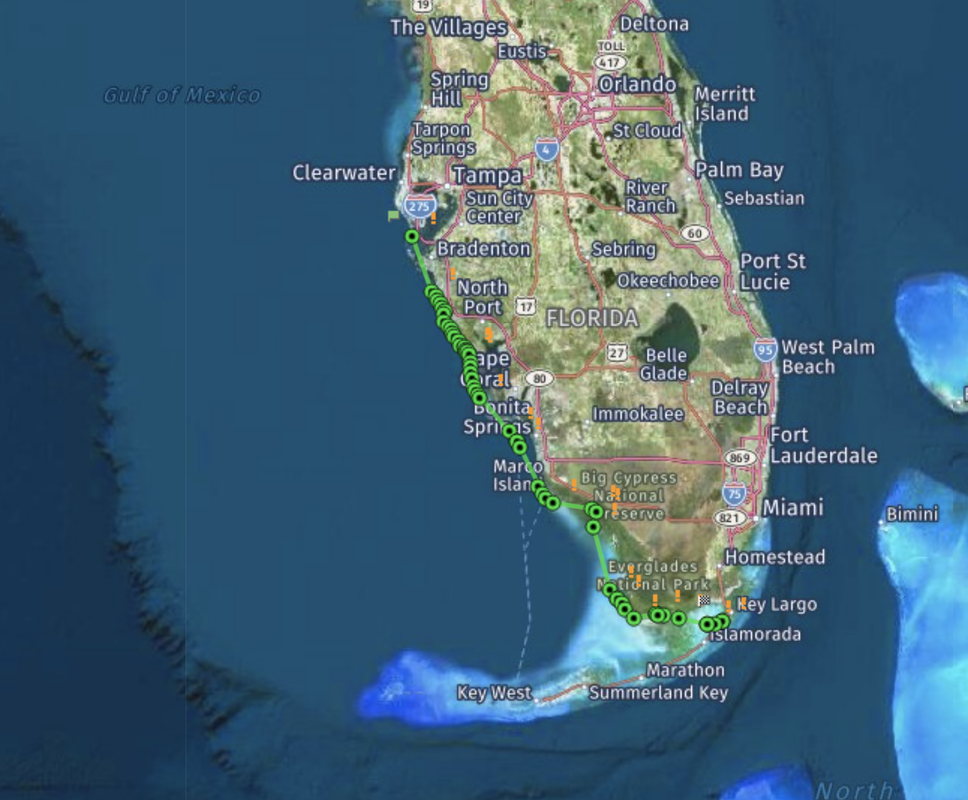

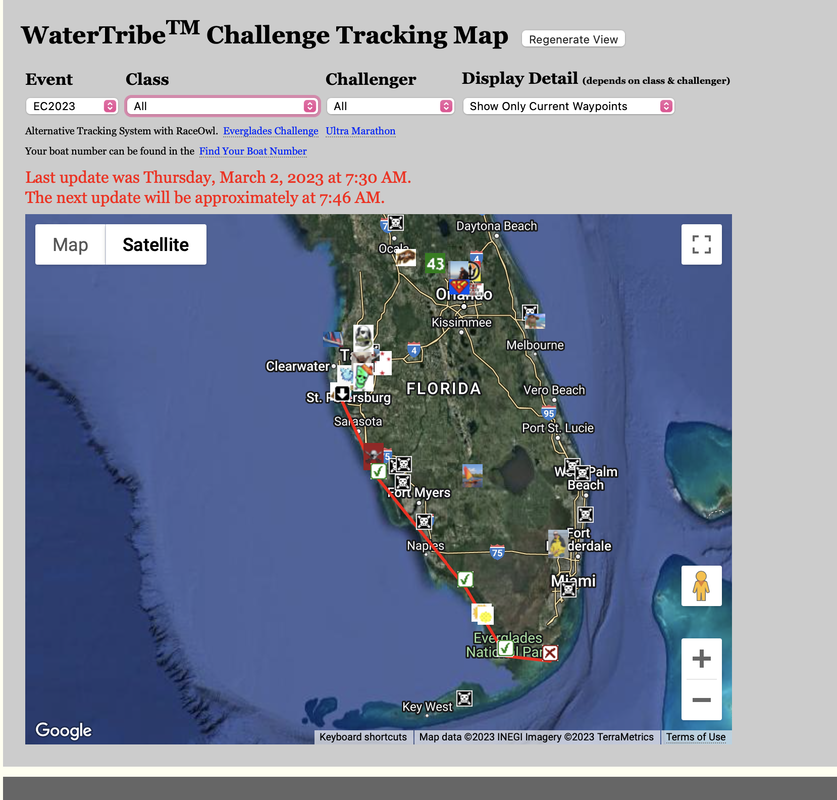

The 2024 Everglades Challenge is off. Around 77 boats pushed off Fort DeSoto beach this morning at 7am (or before 8, anyhow—not all boats were chomping at the bit). This is the annual dash from St. Petersburg, FL to Key Largo by human-powered small craft. The 300-mile course traverses the Everglades and has an 8-day time limit. My favorite skipper, AKA TwoBeers, and his crew Jahn "Moresailesed" Tihanksy made a graceful transition from sand to water. After nearly a decade of complaints about the spotty SPOT coverage, we switched to a personal tracker that seems to be tracking more reliably. Garmin InReach. Hurrah! And Team Spawn even got it working the first try! So far (five hours into the event) the WaterTribe site is glitching, so here's another option if you want to track at home... RaceOwl is the site. Click on the photo below to get to the event tracking page. Fingers crossed for a pleasant event for all the sailors, paddlers, rowers, and those of us on the shore!

A clarion is a kind of horn. Have I heard it (like outside the dubious reality of a Ye Olde Rounde Table movie or two)? Yes. Yes I have. It has a deceptively bovine undertone, as when the annual beach launch of the Everglades Challenge is started by a blast on a conch shell. The Everglades Challenge--again? Yes, why not? My favorite skipper and his Spawnster cohort Jahn Tihansky have been hitting that beach off and on for the past ten years. They start at dawn on the first Saturday of March, pointing the bow of the boat across Tampa Bay and hurrying south. Familiarity has bred something that is not contempt, (we rightly fear hubris) but... anxieties have calmed with the years. A 300-mile unsupported adventure race looks daunting until a team completes it successfully more than half a dozen times. And after their BIG year, when they did the 1200-mile Around Florida Challenge--? Well, ten days of rations, sleep deprivation, cold fronts, and soggy clothing DOES put a 2-day adventure into its place. Someone recently suggested that I should write about TwoBeers and Moresailesed's adventures on Spawn for my next book. Only tell it from my perspective. I don't believe I've ever had a different perspective on the event. In the "READ NOW" instructions for the event, the organizers spell the risks without ambiguity: "You could die." Even more than usual, they mean. When humans take to sea in small ships, it's intrinsically dangerous. The organizers repeat their warning a second time a few paragraphs later, possibly just because my anxiety responds well to a bell tolling. So from my perspective, this is a more-than-usually worrisome event. Yes of course I could obstruct or attempt to gently dissuade my mate from his passion, but where's the win in that? Knock wood we should have a few adventures, all of us, before the curtain drops. So from my perspective, I can aid and abet, organize the ground transport, and pack a bigger medical kit for them. I'll help them get to the beach, knock wood, watch them launch into the briny deeps, and knock it again, meet them at the finish. For 2024, I am low-key psyched to announce I will NOT be complaining about the SPOT. Instead of that spotty old personal locator, we upgraded to Garmin InReach. Nearly every person we know and many we do not know recommended it. And atmospheric conditions (not to mention nudge-nudge "solar flares") willing, we should be able to track our hero's path... As always, the WaterTribe site has a tracking map. It tends to glitch and lag, and you must select the right event to see what's going on. Here's that link: (Sorry it looks rough, my website host has been balking at letting me make it a nice, bougie-looking link.) https://www.watertribe.com/Events/ChallengeGMapper.aspx Here is the Garmin InReach link. It shows only our guys, so it's less useful for checking on the race, but you know, nothing's perfect.

share.garmin.com/N9OY8TwoBeers Ah, February. The shortest month. Around here, it feels like the real start of the year, as if January was just a trial run. After taking a practice stab at the year, we line things up and set sail. Literal sail, actually. In February, there are no real free weekends. If we are not racing together on the Flying Scot, my favorite skipper is competing with others, and if it's not a regatta, it's prep time for the Everglades Challenge. Because that's the time of year it is. Mr. Linton went to Lauderdale with the fiercic37class.org/schedule/ic37-winter-series-lauderdale-cup/e IC37 team New Wave (they prevailed! Yay!). https://ic37class.org/schedule/ic37-winter-series-lauderdale-cup/ We made our pilgrimage to Lake Eustis (and the Oyster Troff) to race our mighty Scuppernong at the Flying Scot Midwinters (illness prevailed! Ugh!) theclubspot.com/regatta/NlXOS3p10P/results The Classic Moth Midwinters, which my favorite skipper and I host, launches Saturday. Hoping for delicious weather for my porch-light pals. And in between times, whenever the schedule allows, while I've been working on book promo and (oooh!) writing the next one, Mr. Linton fixes up the Spawn of Frankenscot. The Spawn of Frankenscot is a sloop that Jeff built to a design OH Rodgers and he specifically dreamed up for long-distance coastal adventure racing. In 2014, Jeff and his crew Jahn Tihansky first pushed off the beach in St. Pete and hurtled down the coast to Key Largo in the annual Everglades Challenge human-powered race. www.watertribe.com/events/evergladeschallenge/ Our team of doughty Spawnsters has done very well for a decade: they hold various records in the 300-mile long race, and even, in 2022, won the 1200-mile extended version of the race known as the Around Florida Challenge. www.amysmithlinton.com/blog/and-just-like-thatthe-racers-came-home But with the start of the new year (in February, natch) comes refurbishment for Spawn. What needs replacing in a mothballed sailing sloop after a year? Thanks for asking! This year the biggest piece of new gear: a new storm jib, made by himself with help from Rod "Rappin Rod" Koch using Masthead Enterprises machines. The wires that hold the mast in place (shrouds) got refreshed. All of the velcro that attaches the storage and sleeping quarters (what looks to me like a conestoga wagon tent affair) got replaced. The bearings froze in the sliding rowing seat, the repair of which gobbled up an afternoon seasoned with solvent and elbow grease. Even with an extra day in February this year, whelp, it's flying.

Going into the 2023 Flying Scot North American Championships, my favorite skipper verbalized his philosophy this way, “I’m going to let the race come to me.”

Well, okay, your highness.

Being strictly honest, however, I knew exactly what he meant. After lo these many years of racing together, we've come to share this sense of regatta destiny.

Here’s what we know as fact: You can lose a regatta from not preparing.

But the only way to win a regatta is to have at least one helping of good luck. Preferably many helpings.

Corollary truth: While you can be ready for good luck, you cannot force it to show up. In a word: destiny. It was the usual Flying Scot good fortune that met us when we pulled our camper and the mighty Scuppernong into the spacious grounds of Lake Norman Yacht Club. Locals Tim Porter, Steve Shaw, and Dave Rink and our fellow road-show gypsies –– the Cliftons and dear Henry Picco –– had saved us a prime parking spot overlooking the swimming beach and the hoist.

Before long, more Florida teams joined in –– Donna and Jon Hamilton, Dave Helmick and Caroline Chapin, Jennifer and Michael Faugust, PJ Buhler and David Ames, Laura and Scott Marriott, and Jim and Pam Burke.

Measurement was as neatly organized and well-thought-out as any we remember. Preparation being key. The weather looked promising: aside from haze from Canadian wildfires and the occasional pop-up thunderstorm, we looked forward to good sleeping temperatures and peaceable breeze in the range we like the best: 7-10 knots.

In actual fact, we sailed under beige, smoke-darkened skies, and the predicted winds –– not unexpectedly, given how regattas go –– did not quite appear as promised. Still, even after a drifter of a single qualifier race, the future looked pretty bright. After all, the race organizers fed us morning and night and provided any number of adult beverages (plus a bourbon tasting!).

Once the wind filled in on Tuesday, we headed out to the racecourse to start the actual competition. We checked the current (yes, it’s a lake, but one whose levels are carefully managed) by tossing our sponge into the water by the starting buoy and counting to one minute. During the qualifier, current set us away from the start at one boat length per minute –– try charging that line! On Tuesday, it was far less dramatic, giving us just a nudge away from the starting line. The four-legged race showed us a little of Lake Norman’s tricksy, lakey quirks in decent 7-knot-ish conditions but we managed to win the first one.

On Wednesday, we packed our apple-and-peanut-butter stacks, our salami-and-cheese rollups, our Gatorade, and our beer for the day. I fondly remember once sailing to the starting line on a Lightning racecourse in Ecuador and having the guys in the boat next to us look –– and then with comedic exaggeration look at us again before exclaiming to one another: “THEY’ve got BEER!” Indeed we do. So there.

The story-telling highlight of the day involved a pontoon boat trailing an inflatable laden with children. We were sailing at a pretty decent clip along the right side of the windward leg, close to shore, with Tyler and Carrie Andrews. the boat builders and speedsters, just behind us and two other lines of boats to leeward when, like a tugboat with a barge under tow, along comes the pontoon boat. Crossing right in front of our bow –– I mean, a boat-length or so in front of the plow-like bow of the mighty Scuppernong. It's a fact that nobody looks stupider to a racing sailor than Johnny Powerboat Driver taking a leisurely tour of the racecourse. And to be fair, it’s a free country. But as Carrie and I agreed, these pontoon people must have had it up to HERE with those kids.

Belatedly noticing the fleet of pointy boats, each driven by a fierce-eyed competitor, and possibly heeding the suggestions of said competitors, the powerboat driver punched the throttle and made an abrupt left turn. The float whip-lashed over the wake, and, as night follows day, it caught air and landed with a breath-taking wobble. But good luck (and possibly preparation) allowed the youngsters to hold tight. But jeesh.

Intense, focused sailing (is that a puff? can we connect? Yes, trim a touch.) gave us a 3rd and a 1st at the end of the day, leaving us a decent lead. No lead, however, is safe, especially on a lake and with competitors like anyone in this fleet.

Cue Thursday, when we set sail in conditions where everything seemed magnified. Puffs were bigger. Shifts were bigger. Holes were bigger. In the space of a few minutes, we’d go from fully hiked and vang-on to me on the low side, struggling to keep moving, while boats all around us were experiencing wildly differing conditions.

We didn’t find a pattern to predict the shifts: oftentimes, the wind will oscillate at a regular interval, or a cloud will indicate a puff, or wind will touch down in such a way that the initial header modulates into a lift. These conditions were like what bull riders call a "honker." No telling which way the beastie was going to buck and twist. After deciding not to hit the middle of the course, we found ourselves in the middle of the course on the first leg. When we might have tacked and ducked a bunch of our competitors, we hung left and got hung. We passed boats and we got passed back again. It was one of the most frustrating hot-and-cold days of racing I can remember. We clawed our way into 5th for the fourth race of the series, watching our comfortable cushion vaporize. Heading into last race of the series –– a 3-legger to finish us closer to the club –– we did not talk about the stakes. We never do. The conditions continued to span the spectrum, with puffs as high as the mid-teens with drifters in between. We went left and, as the phrase goes “got smushed.” We sniffed out a puff or two and made some gains downwind, noting that the wind was tending –– inconsistently –– to go left. Halfway up the last leg, we had a clear lane to go left. Leaving a lake-smart team like John Eckart and Ryan Malmgren, who were bee-lining for the right-hand shore, took some nerve. Not my nerve. But as we got closer to the left side of the course, we could see the flags on the finish boat showing a 30 or so degree shift. A favorable shift, at that. When the puff came to us, we eased first for speed, and then took the lift (Ding! Ding!) all the way to the finish line, sliding into fourth place behind local skipper David Rink. With that, by a single lucky point, we won that shiny belt-buckle of a trophy.

We’ve notched that belt a few times, but it’s always a thrill.

Thanks to the excellent organizers headed up by Tim Porter (and Jennifer), the steely-nerved race management under Matt Bounds, and the amazing Florida Flying Scot District, whose competition (six of us in the top 15 of the Championship, with two top 10s in the Challenger Division) that make us all faster and better sailors.

The tarpon shot out of the water like a fleshy javelin, intent on gobbling a bait fish. Four shiny feet of muscle and eyeball, it landed all willy-nilly in the water a scant boat-length from Spawn. Then another silverking leaped and belly-flopped. Then another. And another. "Whoa," commented one of our weary sailors. "Yeah," replied the other. Just another day off Cape Sable. TwoBeers and Moresailesaid brought their 22-foot boat, Spawn, safely to harbor in Key Largo on Monday, March 6 at around 6 pm –– after a 300-mile, 50-hour Everglades Challenge. They were first to finish, having worked through a pack of boats that started ahead on the course. The event is unique in many aspects, including the sometimes-fluid starting line. This year, for instance, the weather on Friday before the start was fairly gnarly, with an on-shore gale and a big surf pounding. In fairness, it was not awful by tee-time the next day, but as Moresailesaid has said, "To finish first, first you must finish." Of the 80 or so boats competing, only about 20 (including Spawn) chose to start traditionally, pushing off the beach at Fort DeSoto park in St. Petersburg. Others drove down the coast and put in where they felt comfortable. At checkpoint 3, a spot deep in the Everglades National Park notable for poor cell coverage and a resident salt-water croc who likes to keep an eye on the boat-ramp, Spawn had unwelcome congress with a manatee. Tethered to the dock, with the sail up while Moresailesaid went to check in, Spawn suddenly began moving to windward. Then there was a bit of gentle gyration until a quick-thinking TwoBeers raised the centerboard. The manatee mating frenzy continued apace, but without the non-consensual participation of the boat. Without a "yes," o manatee, it's "NO." Departing Flamingo, our sailing heroes used their wiles and ways to get past their last forward competitor by splitting tacks around Joe Kemp Key. Instead of using the usual channel, the boys went east. Skittering along in the very skinny water, says TwoBeers, "Is not for the faint-hearted. There are lots of wading birds. You have to ask yourself, are they seagulls or are they herons? If it's herons, cool." Among the spectators on shore, eagle-eyed Rappin Rodney Koch called it: "No risk-it –– no biscuit." For around three miles, the team navigated by appropriate sea-birds. Perfectly innocent sharks minding their own sharky business were startled out of their wits, half-climbing, half-swimming to get out of the way of the boat as it whistled over the shallows. But the route cut off enough distance to put Spawn in the overall lead. Says TwoBeers of navigating that section of Florida Bay, "My socks were dry the whole way until the end of Twisty Mile. We had to get out and push the boat for the last 100 feet to get to the deep water toward Russell Key." How much sleep did they get? A princely three hours a night! The conditions were favorable for the odd daytime nap and even a rough watch-system. Did they run out of food? No! They enjoyed fried chicken dinner twice, plus plenty of granola bars and other snacks. At the dock, there was ample water and ––ahem–– two beers left in the cooler. Why does their track have long time-gaps? Mostly because their SPOT tracker is not very good at its job, but also because the entire SPOT system (so we hear) went down briefly on Sunday night. And yes, FULLY AGREE, a Garmin Inreach is the better option. How much rowing did they do? More than a few hours, TwoBeers admits. But it made the difference between first and fourth place when they were able to navigate in no wind and foul current, especially in the passes around Choko and Flamingo How long did it take? 50 hours. Saturday at 10 through Monday afternoon. Two full nights's sailing. It's not their longest trip (60 hours), nor their shortest (33 hours). On the eye-of-the-beholder scale, I give it about a four out of ten: They looked tired, but not wrung-out; raspy but not death-defying; creaky but not gimpy. Neither fell asleep in his dinner. Amy's favorite anecdote so far? Typically, I don't hear all the most "exciting" details for a day or two. My favorite skipper is a considerate husband and doesn't like to alarm me all at once. Still, I liked this, overheard over breakfast at Mrs. Mack's: "Yeah, I was glad to be going out Gasparilla in the dark. We could hear the waves breaking, but we didn't have to see what we were getting into." What's it like at the finish line? The finish line is a pocket beach at a little 1950's style resort on Buttonwood Sound (the inside of Key Largo); the welcoming committee included Paula Paddledancer, the Chief, our dear Flying Scot friend Jim Signor, some extra WaterTribe shore crew, and a sprinkling of hotel guests who get a surprise floor show as the boats arrive amidst cheers and a random conch moo. Evidently, one of the liveaboards in the Sound has a conch and he's not afraid to use it. And the big question, of course, is Will they do it again?

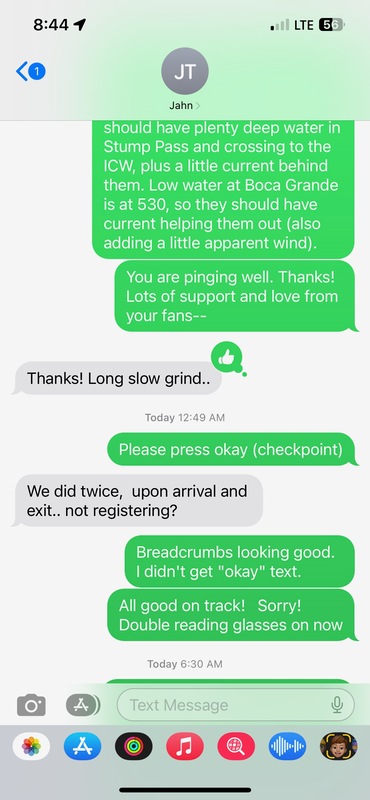

We shall see. Meanwhile, it's not a joke that Spawn is available for purchase. Turn-key operation. Proven winner. Complete Ultimate Florida program available! No tire-kickers please. Fine. It's Day 2, but it feels like the second month of this unsupported adventure race from St. Petersburg to Key Largo. Over the past nine years, this Sunday in March is traditionally the day when I juggle my electronic tracking stuff and hustle myself to Key Largo. Toting a boat-trailer and fresh clothes and such trappings of society as fit in the vehicle, I drive distractedly while my favorite skipper and his communications officer JT slalom down the left side of Florida aboard Spawn. I often joke that after checking their SPOT locator from the rest area on Alligator Alley, I have to skedaddle in order to get to Key Largo ahead of my sailors. This year? No skedaddling required. They might, as I type this Sunday night, have another 18 hours to go. Slowly, slowly are they making their track south. So it's a draggy race this year, one might say. Draggy but not without drama: what with having some Challengers start half a leg or a leg ahead because of Plan B, and the tracking a bit of a mess –– and with the extra complication of having Spawn's personal locator SPOT suffering some form of hysteria that makes her operational lights flash as if she's working... but lemme tell yah: she ain't working like she flashing. Anywhahoodle, the Spawnsters seem to be in good spirits. I am a bit concerned that they might run low on snacks (for once), but since they once fueled half the event on Little Debbie Snackcakes and salted peanuts in a packet, I trust they can fend for themselves. And didn't TwoBeers pack a fishing line? As Paula Paddledancer (organizer and all-round-Mamma Bear for the event) pointed out –– the racers are going to have a pretty night of it anyhow.

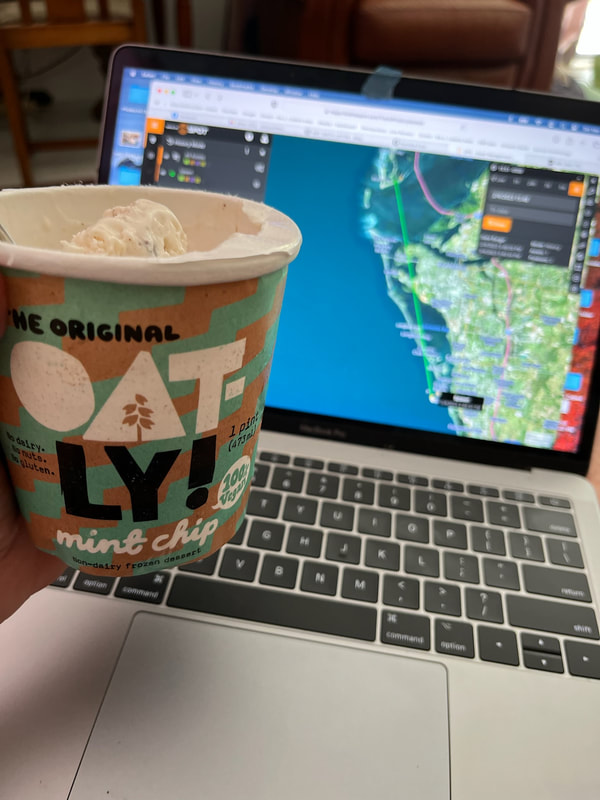

Have I mentioned the wracking of nerves that is the Everglades Challenge Experience for Shore Crew? No, we shore-folk aren't taking red-tide flavored breakers over the bow. No, we aren't sitting in our damp sport clothes for days at a time (I speak for myself anyhow). Neither are we watching for flotsam, marine life, and poorly-driven powerboats. Nevertheless. While waiting for team Spawn to reboot their malingering SPOT personal locator this afternoon, I channeled my nervous energy to good: I washed and refueled the van, I vacuumed, I pressed the reload button several dozen times. I texted and e-mailed Moresailesed and resisted the temptation to leave a frustrated voice-mail about CHECKING the dang SPOT. I knew they had their hands full. I knew they THOUGHT the SPOT was working. I knew they were cheerfully squeezing as much speed from the wind as they could, knowing that the conditions are liable to turn flat and light overnight. Nevertheless. When one of the other shoreside crews called to inquire my opinion about how many half-gallons of ice cream were recommended to help her through the week, I said, I didn't know, I only purchase pints at a time. [On reflection, it was a brace of pints today, which––Huh!––adds up to a half-gallon. Never considered that math before. Answer: one per day, I guess.] This is not the time to keel over from starvation. I jest only a bit. I hope my water-bound Spawnsters have snarfed many pieces of cold fried chicken, homemade chocolate bar, and savory chunks of home-dried beef jerky. Neither sailor is especially food-motivated, but they too have a smorgasbord of things to tempt them. Jelly beans, dried whole tiny bananas (monkey guns, baby!), jars of trail mix, banana bread, a stash of strawberry-yogurt-covered pretzels. Of course, I cannot make those sailors of mine do anything from here on shore. Not eat, not check the dang SPOT, nothing. We can but watch and wait and keep fingers crossed. Here's their SPOT link, which seems to have had a revivifying nap and is back to work. The WaterTribe website has been working for approximately 15 minutes over the course of the past 6 hours by my reckoning. And so it goes.

In light of past years' performance, I anticipate a few cri de coeur about the failings of SPOT as a personal locator, but new year clean slate, right? The personal locator is how the tracking maps keep track of the 100+ adventurers. So, while sometimes the locater maps are slow, sometimes it's the personal locators corking the bottle. The SPOT is a hockey-puck sized piece of kit that promises to ping a satellite every 20 minutes or so. It also has a couple of buttons for specific messages ("We're OK!" "We're in trouble, but we're safe," and of course the panic button that calls the Coast Guard). It's proven finicky. Yes, we have heard that GARMIN makes a superior product with far nicer interfaces and reliability. Had we the option ten years ago, we would have chosen differently. The SPOT hasn't failed, really, but it's disappointed me by not performing as I hope. We weren't ready to invest in yet another piece of expensive electronica for Spawn, so we'll be SPOTTING again this year. Here's a link to that website. It follows Spawn only.

How long will the adventure last?

I have an entire country-western song bemoaning that exact question. It's already playing in my head. The short answer: we hope the gang starts arriving in Key Largo on Sunday evening, but the awards ceremony and official end of the time limit is the following Saturday. It's really anyone's guess. Knock wood. |

About the Blog

A lot of ground gets covered on this blog -- from sailboat racing to book suggestions to plain old piffle. FollowTrying to keep track? Follow me on Facebook or Twitter or if you use an aggregator, click the RSS option below.

Old school? Sign up for the newsletter and I'll shoot you a short e-mail when there's something new.

Archives

June 2024

Categories

All

|

RSS Feed

RSS Feed